Investing in the right robotic gripper for your production lines is an important decision that can help to improve efficiency, reduce costs, and enhance compliance with industry standards. Unfortunately, it can be challenging to identify which robot gripper would work best for your specific needs without a thorough understanding of how they operate and how they could benefit you and your business.

To make this process easier, we’ve put together ten reasons why investing in a robotic gripper could be one of the best investments you ever make – from increased productivity to lower maintenance costs. Read on for more information about each one.

What Is A Robot Gripper?

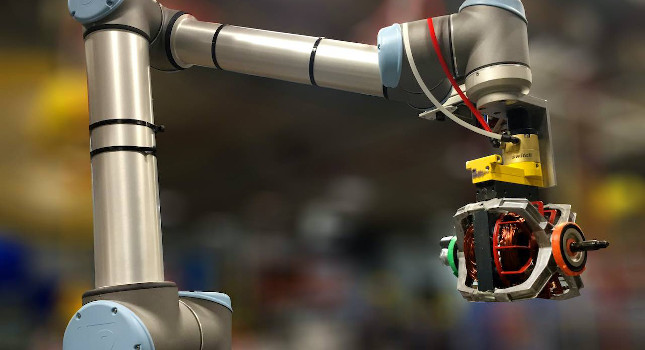

A robot gripper is an automated tool that performs a range of tasks. It includes picking up and moving objects, gripping things in place while they’re being worked on, and even performing assembly operations. Robotic grippers come in many shapes and sizes, from standard two-finger models to customized multi-fingered designs. Still, the principle behind each one is the same: using mechanical components to securely grasp items for further manipulation or production purposes.

10 Reasons Why You Should Invest In A Robot Gripper

Here are the ten reasons why you should invest in a robot gripper:

Increased productivity: robot gripers are designed to perform multiple tasks in a fraction of the time it would take human labor to accomplish them. Robot grippers can dramatically improve your production rates and throughput, ultimately increasing profits.

Improved safety: robot grippers reduce the risk of workplace injuries or accidents by providing an automated and efficient way to move and handle materials with minimal manual intervention. They also improve compliance with industry standards for safe working conditions and reduce potential liability costs associated with workplace incidents.

Reduced labor costs: robot grippers eliminate the need for manual labor, which translates into lower payroll expenses and improved return on investment (ROI). It also allows you to reallocate resources to other business areas, providing a more significant overall financial benefit.

Improved quality control: robot grippers are designed to accomplish tasks with precision and accuracy, leading to higher product quality and customer satisfaction. It also minimizes the risk of human error that could result in costly mistakes or rework.

Enhanced flexibility: robot grippers provide an automated solution for loading, unloading, and moving materials, allowing you to quickly adapt to changing conditions or requirements without needing additional manual labor or reconfiguring production lines.

Increased reliability: robot grippers are programmed for consistent performance over time, reducing the risk of machine failure due to operator fatigue or distractions caused by manual labor. This reliability also reduces downtime, improving production rates and customer satisfaction.

Reduced maintenance costs: robot grippers require minimal maintenance, as they are designed to operate without close supervision or regular servicing. They can remain in operation without needing expensive repairs or replacements.

Increased scalability: robot grippers are easily scalable, allowing you to add additional machines as your needs increase without reconfiguring your production lines or purchasing additional manual labor. It makes robot grippers ideal for businesses looking to expand their operations.

Easier integration: robot grippers are compatible with existing automation systems, making them more accessible and faster to implement than manual labor. It also means that businesses can benefit from robot grippers more quickly and with less disruption to their existing production processes.

Improved customer satisfaction: robot grippers provide faster turnaround times for customers, resulting in improved customer satisfaction and loyalty. In addition, robot grippers are explicitly designed with the customer in mind, providing a reliable and consistent service that ensures customer expectations are met – leading to higher overall satisfaction levels.

The Bottom Line

Investing in robot gripers is an important decision that should be taken seriously, but it could pay off significantly over time. With all the potential benefits outlined above, we believe it’s well worth considering robot gripers as part of your automation strategy, and the ultimate decision is yours.

By investing in robot gripers, you could benefit from increased production rates, improved safety, reduced labor costs, enhanced flexibility, and more – leading to a healthier bottom line and better customer service.

Ultimately robot grippers can be an excellent addition to your automation strategy. They are designed with precision and accuracy in mind, offering improved quality control, reliability, and scalability – all of which can translate into increased profits and customer satisfaction. Plus, robot grippers require minimal maintenance or manual intervention – leading to further cost savings over time.

So, if you want to improve your production process, robot grippers could be the perfect solution. Investing in robot gripers now could help you reap the benefits for years to come – and it could also put you ahead of the competition.